One aspect of aviation knowledge which immediately separates the general public from professionals or self-educated enthusiasts is the matter of aircraft engines. Most members of the flying public are happy to step on and off an airplane, reaching their destination without thinking at all about what has powered them there. For pilots, engineers, and many other employees of the aviation industry, however, familiarity with different engine types is a crucial aspect of safety and strong job performance. Private pilots who do not fly professionally are also expected to have an understanding of the aerodynamic principles behind the engine, which enables them to take off, cruise, and safely land. Learning about engine types of the past, as well as how engine affects performance, provides a strong basis for appreciating the forces of flight.

Piston Engines

Piston engines driven by a propeller are no longer used in large passenger aircraft. However, these are still popular in smaller airplanes. Anyone with an interest in aviation should develop an understanding of piston engines, as these are what the first airplanes used. Piston engines operate with crankshafts, and valves which open and close are regular intervals.

Orville and Wilbur Wright asked several manufacturers which produced gasoline engines for automobiles if they could build one to their specifications. None did, and none seemed interested in trying. They then asked a machinist, Charlie Taylor, for help. Taylor, who had never built an engine before this attempt, managed to construct one without schematics or even an overall drawing. Working side by side with the brothers as they constructed the airframe of their Flyer, Taylor knocked out a twelve horsepower engine which weighed 178 pounds. He did so in only a month and a half, with some tweaking required. Since the Wrights asked for an engine under 180 pounds, which could produce eight horsepower, they were pleased.

While this engine seems laughably small by today’s standards, it was all the Wrights needed, and the fact that they and Taylor could cobble together such a product so quickly without other guidance is nothing less than astonishing. Still, Taylor and the brothers operated on the principles of a basic reciprocating engine, which had long been used to power steam engines.

Flying With a Piston Engine

Most pilots begin their journeys in single-engine piston airplanes such as a Cessna, Diamond, or Piper. Flying with a piston engine means the pilot is working with a loud, generally low-power engine which operates at far lower speeds than even the smallest passenger jet. However, piston engines are also in use in the corporate world. Piston engines are best for flying at lower altitudes when cost is a consideration, and high speed is not a factor.

When flying a piston engine airplane, pilots must have a good understanding of power settings, and under which conditions they ought to be used. This depends on what the pilot is asking the airplane to do. To squeeze the most efficiency out of a piston engine, pilots should optimize the fuel-air mixture in each cylinder.

Turboprop Engines

Turboprop-driven engines work via reverse airflow. Intakes near the propeller drive air to the intake, which drives it in a hairpin turn, then back again in the engine’s combustor. After ignition, the engine’s turbines are activated. The energy generated by this system makes for airplanes, which are usually used for regional travel. Turboprops run on Jet-A, which is cheaper than AvGas. These engines are reliable and easier to maintain than other engine types.

There are several significant differences in flying piston engines and turboprop engines. Pilots who move from a low power setting to a higher one usually report a short lag in the application of power; this is because the additional airflow of a turboprop engine takes time to ramp up the power the pilot has asked it to generate. Turboprop airplanes also use more power than piston engines and are typically more susceptible to torque setting limitations. Pilots also typically find that turboprops are easier to break, and some prefer turboprops because they do not have to be primed as piston engines might.

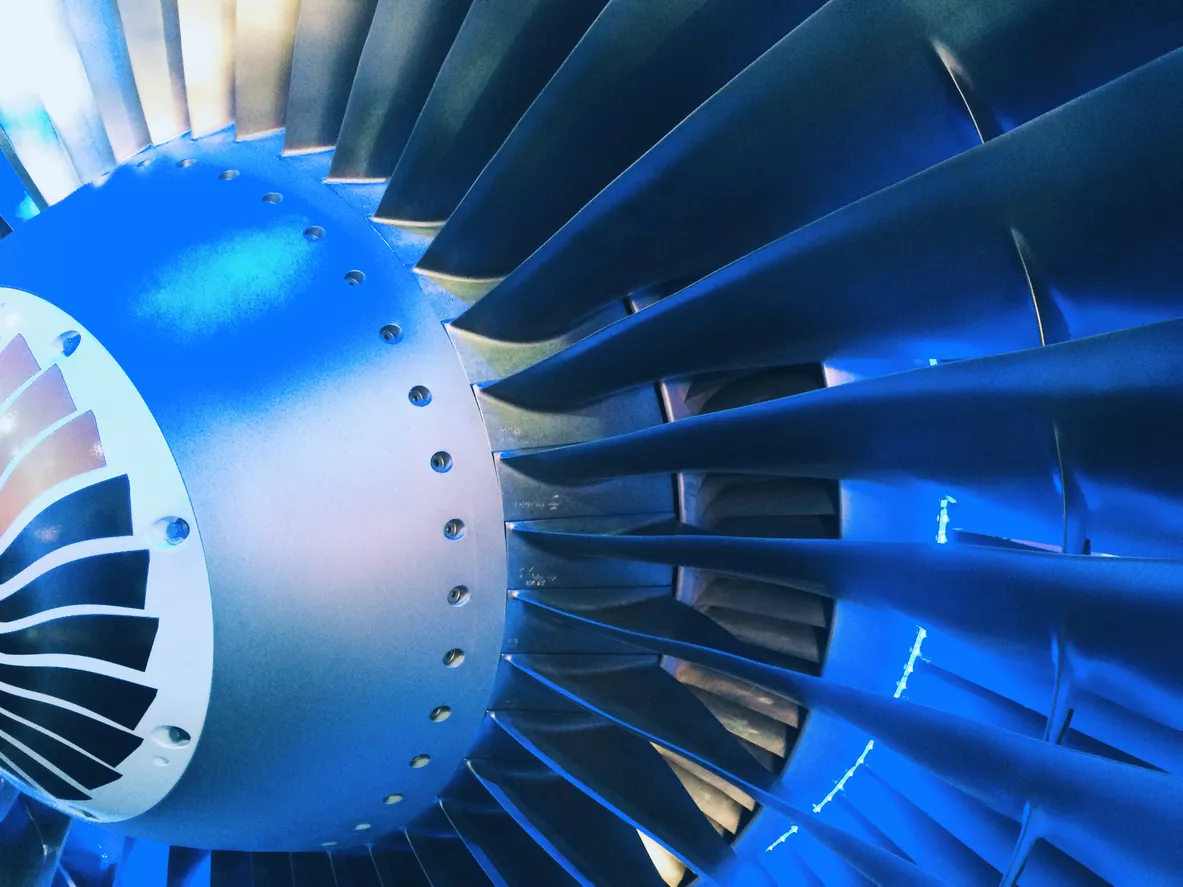

Turbofan Engines

Turbofan engines are a modern invention which combine less noise and fewer emissions, which make them attractive for marketing purposes. They are mostly used on passenger jets. In these engines, a turbofan, compressor, combustor, turbine, and nozzle act in concert to rapidly push air through the combustor. The result is far more thrust than can be generated by piston and turboprop engines.

From a piloting perspective, turbofan aircraft tend to be more automated than piston or turboprops. They can soar above inclement weather and demand a change in approach for pilots used to piston engines. Flying jets, for example, asks pilots to change from altimeter settings to standard settings. They must also negotiate differences in tillers, yokes, and throttles. The cockpit of a jet is usually more complicated than that of a piston aircraft and, indeed, might be all glass, with few if any steam gauges.

Workload might be more intense on a jet, which is why many call for a first officer in addition to a captain. The speed at which jets travel force quick decisions and confidence in one’s command of the craft and environmental conditions. The sleeker aerodynamics of a jet as compared to a piston aircraft also require some getting used to. Pilots must rely on instruments much more than simply “eyeballing” approaches or landings. Study, simulator time, and ground school preparation are key during the transition from a piston aircraft to a turbofan.

Jet Engines on Military Aircraft

Jets can fly higher, faster, and with more capacity; therefore, they’re used on longer flights and almost exclusively for international travel.

Jets are also the core of military applications, particularly fighter jets, which are noted for high fuel burn but tremendous maneuverability. The aerodynamic properties of these aircraft mean that they are typically reserved for only the most advanced pilots, who must command their high-lift capabilities in conjunction with their incredibly powerful engines.

Ready to soar in your aviation career?

Mr. Matthew A. Johnston has over 23 years of experience serving various roles in education and is currently serving as the President of California Aeronautical University. He maintains memberships and is a supporting participant with several aviation promoting and advocacy associations including University Aviation Association (UAA), Regional Airline Association (RAA), AOPA, NBAA, and EAA with the Young Eagles program. He is proud of his collaboration with airlines, aviation businesses and individual aviation professionals who are working with him to develop California Aeronautical University as a leader in educating aviation professionals.